best way to proceed ESPRIT SOLIDMILL CAM MIGRATION or integration

- Turn-key migration or integration using customer's laptop software, posts & license, models & dwg/dxf drawings, work holding, cutting tools & machining parameters, and g-code nc programs.

- No issue with floating license or version.

NC PROGRAMMING SOLID MODELS WITH MINIMUM CONTENT PART DRAWING

Esprit PROFITMILLING (VOLUMILL) DIE OPEN POCKETS

ESPRIT PROFITMILLING (VOLUMILL) DIE OPEN POCKETS

PROFITMILLING DIE OPEN POCKETS

- Video illustration of the Esprit 2013 new "ProfitMilling" feature applied here in open pockets milling with a 1/2" diameter high performance carbide end mill 4 flutes cutting 2.5XD length of cut at 560 SFM 0.0023 IPT using the "Production Milling" software package.

Esprit solidmill production NC Programming 4 axis progressive fixtures Application

machine complete ESPRIT SOLIDMILL PRODUCTION NC PROGRAMMING

4 AXIS VMC 5 POSITION 1 OP

- Aluminum Alloy 6061 BAR 1-1/4" x 4" x 7".

- Progressive Fixturing Machine Complete 1 Op. G54.1 P1-P9

- Cycle Time 24 Minutes.

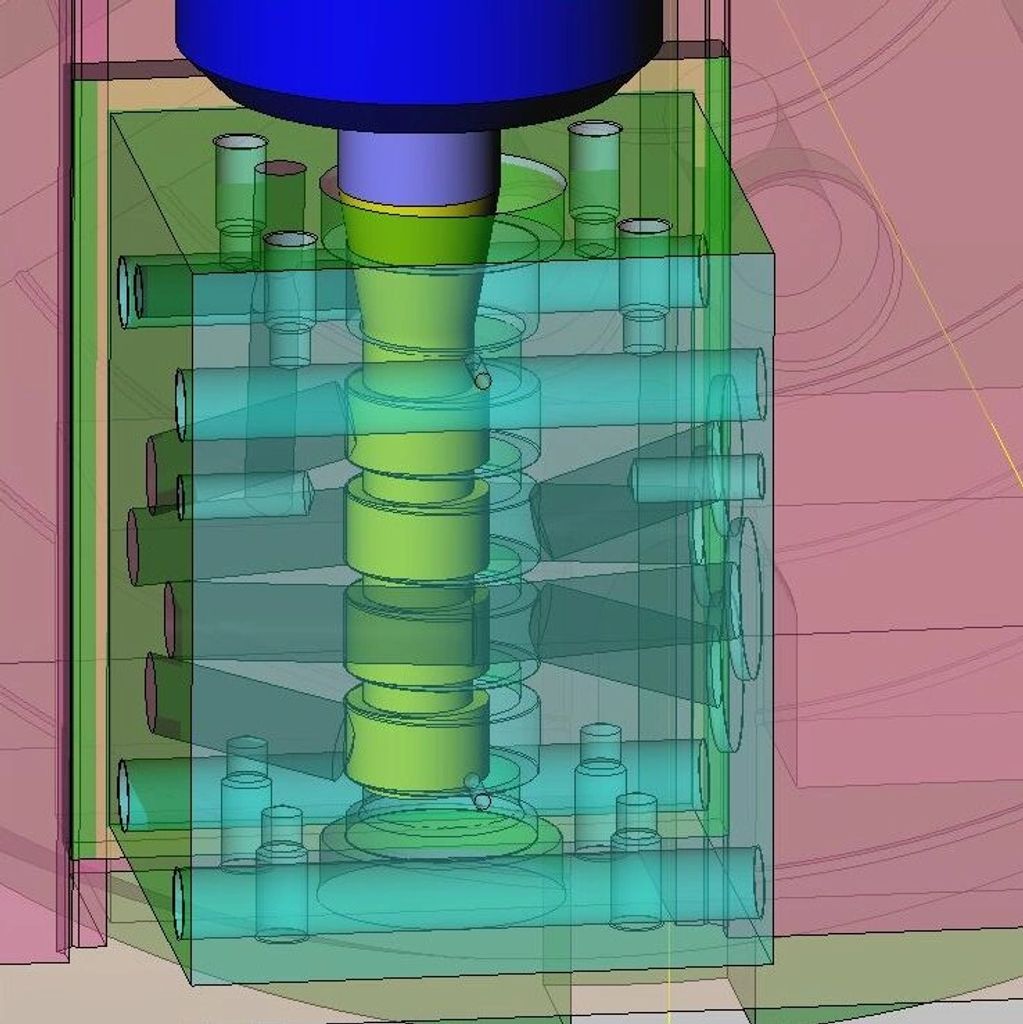

Constant Cutter Load Simulation Verification

- "HIGH SPEED MACHINING". Applications Engineering,

- Constant cutter load ProfitMilling volumetric high speed machining (HSM programming similar too VoluMill) using high performance carbide end mill for roughing and finishing.

Tooling Geometry & Parameters Fully Detailed

Technology Application Engineering.

- Tool & Fixture Design.

- NC Programming.

- ,3D Modeling.

- Optimization.

ESPRIT SOLIDMILL VIDEO ILLUSTRATIONS

WIREFRAME MACHINING W/O FORM TOOLS

- Low volume high mix nc programming illustration for cnc vertical and horizontal machining centers without specially ground form tool, using standard stocked off the self high performance precision ground carbide tools.

- CNC machining process for a BPE BIO PHARM 316L controlled sulfur stainless steel B32-14MP eccentric reducer on a Haas VF-6 3-axis vertical machining center with 1000 psi coolant.

- Deep hole drilling 0.363" diameter 4.50" thru hole no pecks into a pilot hole applying a simple custom drill cycle (black book, trade secret, intellectual property).

- Also, plunge and contour milling with all high performance carbide end mills and a lapped left hand spiral reamer. Maintained a 15 Ra surface finish in the tube bore and ID finishes of 32 Ra or better and OD finishes 63 or better.

- Cycle time approximately 12 minutes excluding the lathe blanking operation.

- Eliminated the tube, eccentric reducer and tangents along with the welding. Made from stocked 1-1/2" diameter bar stock.

- Held in custom vise jaws to suite. .

5-AXIS TRUNNION SERVO VALVE MACHINING

- 5-axis cnc machining process. 3-axis vertical machining center with a 2-axis tilt & rotate trunnion table. NC programmed and post processed in Esprit. Fanuc compatible Haas machine code program.

- Process eliminated manual & cnc mill and drill, cnc lathe id machining and grind 0.00040 flatness.

- Programming time was approximately fifty (50) hours primarily from very reliable imported data (tooling preset dxf drawings including machining parameters),

JOB SHOP "THINKING OUTSIDE THE BOX"

- Existing customer owning 3 local shops for machining, fabrication, welding and casting calls during the weekend asking for cnc machine control repair references.

- Needs to ship 12 trial run parts by the end of the week to a potential new customer for a very promising part future order annual buy.

- Material already purchased and waterjet cut based on cnc lathe machining (facing, turning, chamfering and boring in multiple operations) and the split half weldment prep face and chamfer grinding.

Questions? Problems? Difficulties? Quantitative Solutions: 716-652-4510

Copyright © 2025 Mfg Alliance Associates inc - All Rights Reserved.

Webmaster Dennis Grzymala