GIBBSCAM LATHE MILL YOUR SOFTWARE & PC TURN-KEYED.

GIBBSCAM MILL YOUR LICENSE & HARDWARE

GIBBSCAM 3D MILLING W/O FORM TOOLS

- CAM software milling function w/ standard mill module more low volume high mix cnc programming on cnc vertical and horizontal machining centers without specially ground form tool, using standard stocked off the self high performance carbide tools.

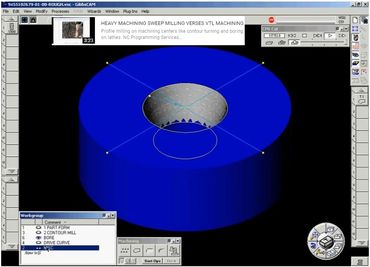

VTL HEAVY MACHINING PROCESS

- Heavy machining NC PROGRAMMING PROCESS for forgings, castings and burn-outs rough and finish facing, turning and boring large parts on vertical lathes, illustrating the application and benefits of the industry standard CNMG insert geometry. .

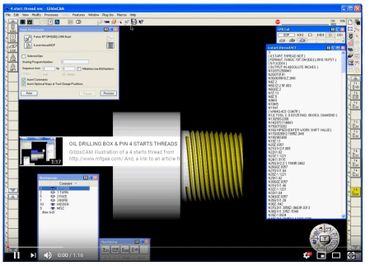

GibbsCAM Lathe 4 Start OD Thread

- OIL DRILLING BOX & PIN 4 STARTS THREADS

FORM TOOL 3D MILLING MILL-TURN

- Septum (heart wall) machined from 1-3/8" diameter titanium bar stock on an Okuma Multus B300W using GibbsCAM Production Mill Lathe software with a Haas 3-axis mill post processor outputting an R value in G03 g-code command.

- Simply cut and paste the g-code from text editor into the OSP machine control unit. Cutting with standard OEM tools and a custom form tool for 3-axis simultaneous contour milling.

- Why? The algorithms provided by many CAD/CAM OEMs may be fine for programming new designs or for product development, but not for production where cycle time effects productivity and machine tool utilization and capacity. Lean: doing more with less.

Detailed Job Shop NC Programming

- This video shows the typical detail we provide in nc programming.

- Supporting documentation is illustrated in the machining process of a hydraulic manifold made from 1018 carbon steel 125Bhn hardness on a Haas TM-1 toolroom mill programmed with GibbsCAM production milling software.

Copyright © 2025 - All Rights Reserved.

Webmaster, Founder