American Manufacturing Methods, Tool Design, NC Programming

| Aerospace | Defense | Medical | Automotive | Power Generation |

| Oil & Gas | BPE | 3A | Machinery | Heat Transfer | Job Shop |

Service illustrations for fortune 1000 companies, machine builders & distributors, and job shops.

Service illustrations for fortune 1000 companies, machine builders & distributors, and job shops.

Service illustrations for fortune 1000 companies, machine builders & distributors, and job shops.

Service illustrations for fortune 1000 companies, machine builders & distributors, and job shops.

Service illustrations for fortune 1000 companies, machine builders & distributors, and job shops.

Service illustrations for fortune 1000 companies, machine builders & distributors, and job shops.

various linked-In articles founder "cnc programming" group 24K members. restricted questioning quantitative data applied to COVID-19 & 2020 election.

posted videos on Youtube 7 of 100 mfgaainc CHANNEL

Benefits of VMC 4 axis & extended fixture offsets for 6 side machine complete 1 operation.

- Illustrated in this YouTube video are designs of an ADAPTER PLATE FIXTURE mounted to a 4th axis platter and an ARBOR FIXTURE and a CRADLE FIXTURE supported by a tailstock shown in various table layouts for examples of their applications. .

- Also shown in the video is an NC program creation for a HAAS VF-5/40 vertical machining center with a HRT-210 4th axis rotary table from an ESPTIT cam template for verification simulation and post processed HAAS machine code in a neutral (not proprietary) Fanuc compatible EIA-244 / ISO-840 format.

High Performance Profile Milling & Slotting

- Parameters: work piece material 8620 steel, cutter diameter 1/2'' (0.500) 4 flute, DOC 1XD and 2XD, SFM 560, RPM 4277, profile IPT 0.0023 or IPM 39, slotting IPR 0.0015 or IPM 26.

Tool Design Setup & Run Time Reduction

- Cutting tool designs eliminating machining operations for substantial cost reductions.

TITANIUM HEART WALL FORM TOOL FINISH CONTOUR 3D MILLING LESS TIME

- Septum (heart wall) machined from 1-3/8" diameter titanium bar stock on an Okuma Multus B300W using GibbsCAM Production Mill Lathe software with a Haas 3-axis mill post processor outputting an R value in G03 g-code command.

- Simply cut and paste the g-code from text editor into the OSP machine control unit. Cutting with standard OEM tools and a custom form tool for 3-axis simultaneous contour milling.

- Why? The algorithms provided by many CAD/CAM OEMs may be fine for programming new designs or for product development, but not for production where cycle time effects productivity and machine tool utilization and capacity. Lean: doing more with less.

304 SS 0.382 DRL 12xD 4.4DP NO PECK

- Work piece material 304 stainless steel grade SA-240-304 thickness 4.38" thick.

- Order quantity 3.

- Deep hole drilling 0.382 diameter hole 187 places.

- Cycle time 2 hours 30 minutes no pecks 1300 RPM 6.1 IPM.

- Machine tool Haas VF-8 with 1000 PSI coolant thru the spindle.

- Same 20 X D flute length drill used for all 3 work pieces in lot, applying a simple custom drill cycle.

Heidenhain TNC 430 .I iso Esprit program 5 side weldment machine complete 1 operation.

- Esprit 2009 5-axis ISO .I program (from our customized Esprit post processor).

- Soraluce SP 8000 traveling column.

- 5-axis positioning (X,Y,Z,A,C) and 3-axis simultaneous with a Heidenhain TNC 430 control .

5 Axis VMC 5 Side Machining 1 OP Work Holding & Tool Assembly Clearance Illustration

- Full length video of a cnc machining process for positioning trunnion and spindle clearance verification while cutting.

HIGH SPEED MILLING TOOLING AND PRODUCTION MAGAZINE.

HSM DIE & MOLD CUTTERS

Ramp closed and open pocket and contour milling mild and stainless steel and titanium and hastelloy materials.

HIGH SPEED MILLING 81% LESS TIME

- COST PER PIECE REDUCTION THROUGH HIGH SPEED CNC MACHINING WITH DIE & MOLD INDEXABLE CARBIDE 3 FLUTE END MILL.

- FLAME CUT SA-516 GR-70 MATERIAL.

- 3000 RPM, 300 IPM, 0.044 D.O.C., FULL W.O.C.

- ACHIEVING AN 81% CYCLE TIME REDUCTION.

- PROGRAM SIMULATED AND VERIFIED WITH LESS THAN 17 MINUTES CYCLE TIME REMOVING 148 CUBIC INCHES OF MATERIAL.

MILLTURN FANUC 31i-B MANUAL PROGRAMMING.

Machine Tool Bulider Concurrent Engineering

- With assistance from your MACHINE TOOL BUILDER, recommend manually program a core product in one operation currently performed in multiple operations on 2-axis lathes and 3 axis mills.

- Use your proven existing tooling and machining parameters in Fanuc, Mazak, Okuma, Haas, etc... controls programmed in EIA / ISO industry standard.

Core Products Carry Over

- Use the proved out manual program baseline part as a template and copy and edit it to create additional core product part programs that meet the machine's constraints.

No Additional CAD/CAM Investment

- No need for a $10K to $35K high end CAM System or special computer hardware or the experienced skilled labor for off-line programming.

MILLTURN FANUC 31i-B MANUAL PROGRAM run off.

With assistance from your MACHINE TOOL BUILDER, recommend manually programming the MillTurn first part and run off at their facility.

Heavy Machining Line Bar Boring

ADVANCED MANUFACTURING engineering quantitative methods

CNC Machine Tool Capital Expenditure Justification

- Heavy machining Industry compressor split halved cases & barrels.

- Sr. Mfg. Engineer Advanced Mfg Engineering project 55.0MM 3 years modernization program.$5.0MM traveling table bridge project (Ingersoll Masterhead).

- Case bay existing machine utilization analysis: traveling column and table planer mills, floor and table boring mills, radial drill presses, line bar boring equipment, and vertical table lathes.

- 3 observations per shift 2 shifts 5 days a week 6 weeks.

- 180 observations ±3 sigma 99.73% confidence level.

Quantitative Methods

"Without data you're just another person with an opinion", W.Edwards Deming, Data Scientist.

Eliminate forgings & castings. reduce inventorY, lead time & lot size. build to market demand.

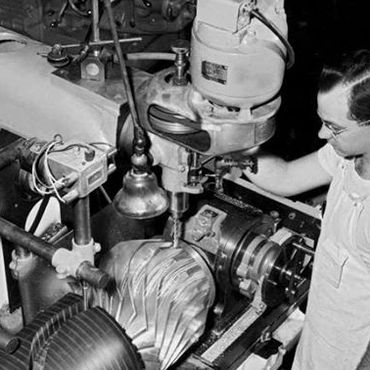

pre-1985 mill 3-axis hydraulic & ELECTRo-mechanical tracers

Aircraft Hydraulic Actuators

- Contour mill simple or complex geometric shape parts with flat, round and irregular surface forms.

- Machine blanks from certified billets and commercial grade materials, holding the typical +/-0.015 tolerances for defense and commercial industries.

- Use simple low end 3-axis simultaneously contour milling software.

- Use older, worn, less accurate machining centers for blanking.

- Design & build custom work holding fixtures with work-in-progress diamond/dowel service areas in 2 or 3 manual index positions or in all 4 quadrants if necessary.

- Bench work the indexed areas like blending flashing while cycling machines semi-unattended.

- Machine off service areas and complete machining process.

.

"Behold that which I have seen: it is good and comely for one to eat and to drink, and to enjoy the good of all his labour that he taketh under the sun all the days of his life, which God giveth him: for it is his portion. Every man also to whom God hath given riches and wealth, and hath given him power to eat thereof, and to take his portion, and to rejoice in his labour; this is the gift of God."

"... he that hath no sword, let him sell his garment, and buy one." Imprecatory Psalm 69, 109, 5, 6, 10, 12, 35, 37, 40, 52, 54, 55, 56, 57, 58, 59, 79, 83, 94, 137, 139 & 143. "How long, O Lord, holy and true, dost thou not judge and avenge our blood on them that dwell on the earth?”

KJV

HONESTY AND INTEGRITY COME FIRST. A SPADE IS A SPADE.

Data Science, Discerning Between Fact Versus Opinion.

"Without the data you're just another person with an opinion", W.Edward Deming, Data Scientist.

Copyright © 2025 - All Rights Reserved.

Webmaster, Founder