Manual programming siemens 840D turn-key project

Additional Information

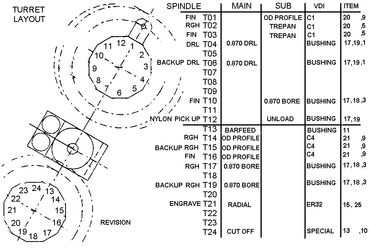

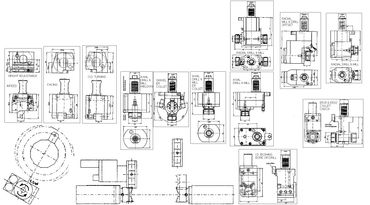

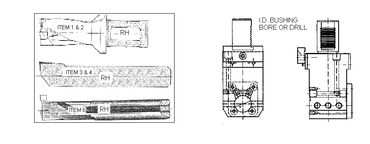

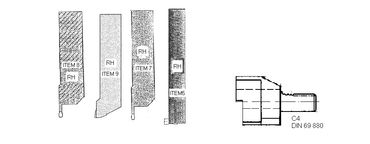

- Illustration for migrating a family-of-parts Fanuc or Mazatrol ISO g-code CNC machining processes to a Mill-Turn 12 axis Siemens 840D control in proprietary format with barfeeder, tool force & life monitoring, and internal gantry part conveyor.

- Start with a baseline part to machine complete with the highest volume and greatest number of inventory turns for the intent of holding zero inventory due to zero or minimal setup.

- Manually program it for a turn-key run-off joint venture with the machine tool builder or distributor.

- Use your existing lathe & mill programming software for simulation and post processing in ISO g-code format, and use the existing proven commercial tooling, machining parameters, and sequencing methods currently cutting in multiple operations on 2 axis lathes and 3 or 4 axis mills.

- Use the proved out manual baseline part program as a template containing all the proprietary miscellaneous function (bar pull or bump-out, spindles synchronization, part transfer, cut-off, c-axis & y-axis positioning * cutting, axial & radial live tooling, parts catcher & conveyor, etc…….).

Template Programming

Applied the same template concept for Heidenhain .H manual iTNC 530 programming heavy machining parts on a travel column with floor plate and index table on saddle with 3 different spindle heads and with CAT 40 & CAT 50 tooling.

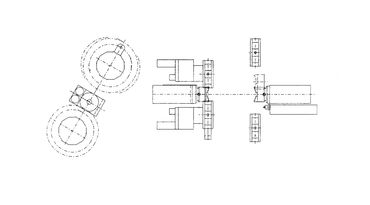

840d mcu Gildemeister twin 102 machining tool layout & sequencing

MILLTURN: MIGRATE MAZATROL ISO TO SIEMENS 840D

CONCURRENT ENGINEERING TURN-KEY AT MACHINE TOOL BUILDER EAST COAST.

DMG Gildemeister MF programmer

Copyright © 2025 - All Rights Reserved.

Webmaster, Founder